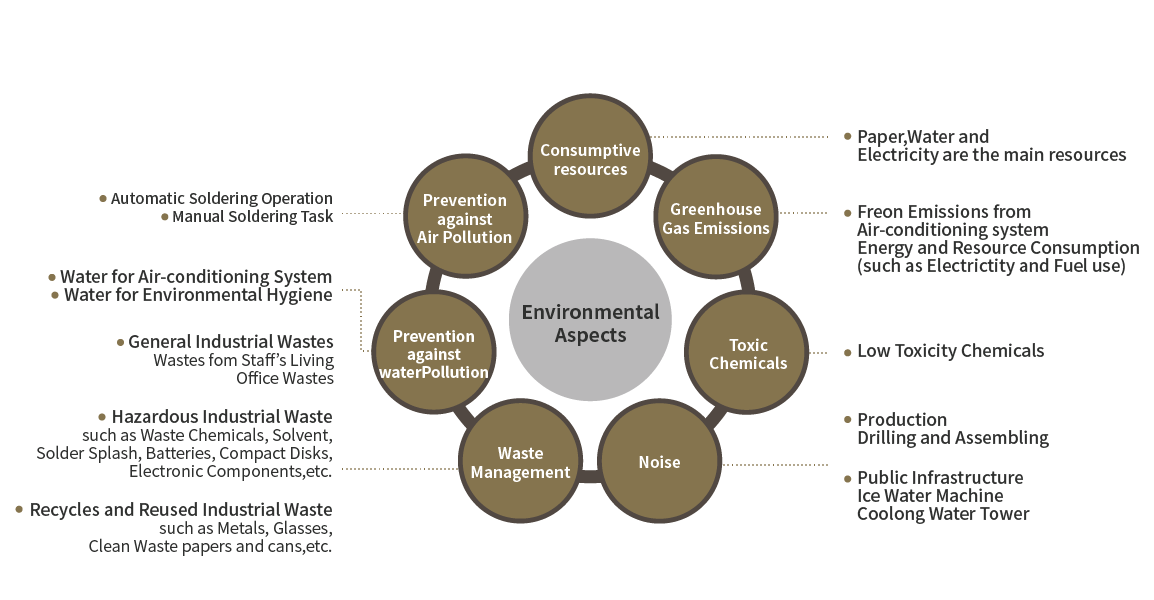

Environmental Aspects

Identify environmental aspects to prevent pollution

Identify existing and future activities, products and services of the company which may have an impact on the environment in terms of environmental aspects so as to implement environmental management.

GHG & Energy Management

Practice carbon reduction to protect the Earth

Pegatron is actively formulating greenhouse gas inventory plans and reduction targets. Electricity usage is Pegatron's main source of greenhouse gas emissions. In addition to striving to achieve higher production efficiency with low energy consumption in the production process, the group implements various energy-saving measures in daily operation management. Pegatron improves the efficiency of power usage by power usage management, lighting management, and air-conditioning system management. Also, Pegatron introduced and passed ISO 50001 energy management system certification.

The implementation policy sets out a greenhouse gas reduction plan. To effectively manage environmental issues, Pegatron has established an appropriate environmental management system, which follows the requirements of the ISO 14001 environmental management system.

PROTEK and GLOBETEK have been certified with ISO 50001 Energy Management System in 2018.

In 2023, Pegatron invested approximately NTD 41 million in Taiwan’s factories for energy-saving and renewable energy equipment, including replacing cooling systems, introducing energy management mechanisms, and installing solar power panels. The annual reduction in carbon emissions is about 1,800 tons CO2e.

Waste Management

Source reduction and appropriate reuse and recycling

The sources of our industrial waste are mainly research and development test materials, scrap, packaging materials and general waste. By strict classification and management mechanisms, we are able to reduce the potential impact on the environment. Pegatron's first priority in waste handling is reuse. Those cannot be reused will be broken down or shredded and recycled as raw materials. Incineration and landfill disposal is our last option. Reducing the ratio of incinerated waste is our goal to reduce pollution.

Water Conservation & Management

Save water resources and implement appropriate treatment

Our manufacturing processes do not consume a lot of water. Because domestic water is the bulk of the water we consume, we encourage employees to save water and set up water-saving devices. Domestic wastewater is discharged into a sewage system and managed by qualified, professional personnel. Wastewater discharged at each plant is managed by individual facilities and complies with legal requirements. Treated wastewater quality is monitored at discharge points and conforms to national standards. Also, the relevant authorities perform irregular sampling and audit according to legal requirements.

Prevention of Air Pollution

Promote green manufacturing to prevent air pollution

Our manufacturing activities are mainly assembly processes. Fumes, vapor, and organic solvents are the main emissions generated from our manufacturing processes. Therefore, potential risk is relatively low. However, we still monitor possible pollutants regularly. The results all comply with national legal requirements. In addition, to further promote green manufacturing, we use environmental and water-based fluxes instead of the flammable organic solvents previously used.